South Yorkshire Times, August 18th 1933

Courage And Enterprise

Manver’s Main’s New By-Product Plant

A Wonderful Installation, Some Interesting Features

Gas For Local Industries

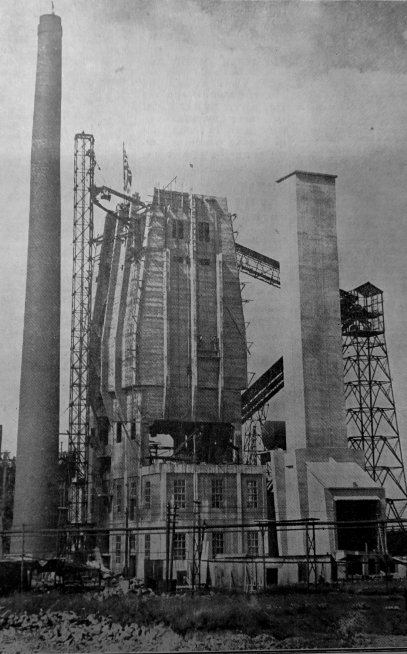

A new landmark has arisen in the history of the Manvers Main Collieries. It has been visibly rising for some months and has at length added a striking feature to the industrial landscape of the district.

A new coking and by-product plant has been erected on the site of the old plant by Simon Carves Ltd., foremost of English coke-oven constructors. There is a difference of a generation of engineering and chemical research between the old plant and the new.

A Brief History

The original plant consisted of 36 Koppers ovens with vertical flues, each oven with a capacity of about seven tons of dry coal. The new plant has thirty ovens of twice that size, with provision on the site for the addition of fifteen. The old plant, which commenced operation in February, 1906, was improved and extended from time to time. Fourteen ovens of the Simon-Carves waste-heat type were added in 1912-13, and a crude benzol plant laid down. Then, with the war demand for toluol, a further battery of 22 similar ovens was added in 1917, together with a benzol rectification plant. After the war, this plant was turned over to the production of motor spirit, and additional plant was erected to cope with increased production of coke-oven gas (for the use of the municipal gas undertakings at Wath and Swinton).

A Bold Step

Finally, last year, the directors of Manvers Main took the bold decision to scrap the entire plant and replace it with a modern installation of 45 ovens, capable of carbonising a thousand tons of washed slack a day. As a first step they demolished 36 of the old ovens to make room for the new, and placed an order with Simon-Carves for the building of 30 ovens of the under-jet fired type, with Otto twin flue, and Wolff patent self-sealing doors. The order was placed in July,1932 and the contract was scheduled for completion on December 1st, 1933. The work has gone forward so expeditiously, however, that that date is likely to be anticipated by two months, and the new ovens will be ready for preliminary heating in a few weeks.

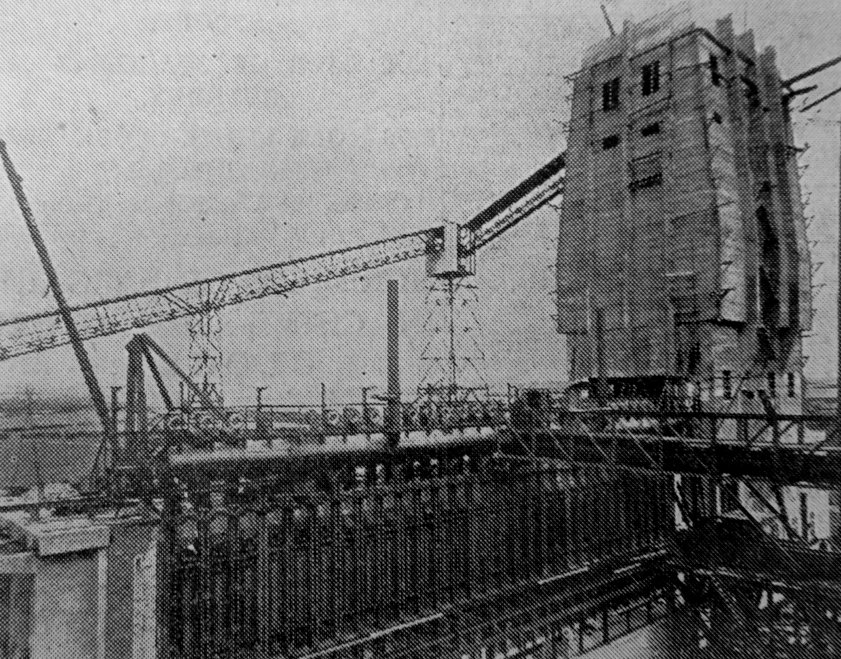

Benzol And Ammonia

The plant includes also collecting and take-off mains, two large condensers, and two smaller ones (retained from the old plant), six scrubbers, 86 feet high and 11 feet in diameter, three for the recovery of ammonia, and three for benzol, exhausting machinery capable of dealing with 572,000 cubic feet of gas per hour, an electrostatic precipitation plant for liquefying tar “fog” and a complete new benzol plant for the production of high-grade motor spirit in two stills, each of 5,000 gallons capacity. The expedition and accuracy with which the plant has been erected is the more commendable because the site, in an angle between the colliery and the railway (L.M.S.), is rather cramped. But that the land beyond the railway is liable to flood, a much more spacious and convenient site could have been found there.

Highly Mechanised

The coke-ovens are of 15 tons capacity, and of the latest design, constructed of high-grade silica and equipped with regenerators of special design. The coal will be brought in wagons to the siding, mechanically tippled into an underground receiving hopper, and delivered into an elevator, thence to a horizontal belt conveyor which will take it forward to the coal service bunker. On the way it may receive from a special plant an admixture of fine coal dust. The coal service bunker, an impressive feature of the plant is of ferro-concrete, stands 140 feet high and has a capacity of 2,000 tons in two compartments, one of 1,600 and one of 400 tons. The smaller compartment is intended for experimentally blended coals for the production of a special type of coke. Special care has been taken to make the plant adaptable to the production of finely graded cokes, and it is intended to produce not only metallurgical coke, but the highest quality of domestic and central heating fuel.

A Fine Chimney

The ovens are charged from an electric travelling car of 15 tons capacity and each charge will be automatically weighed and the requisite weight signalled to the car driver. The ovens are discharged by a Buchanan ram and leveller fitted with an automatic device for dealing with the doors. The plant chimney, which is circular and constructed of Manvers Main brick (straight faced and wedged), rises to a height of 213 feet from its concrete base and is in itself a very fine piece of engineering. Its internal diameter 11 feet at the base and 7 feet at the top. The first 60 feet are lined with fire brick and the last 70 feet with acid-proof material. The chimney is fitted with an Askania governor operated from the control room which houses numerous scientific instruments of the latest type.

The Quenching Tower

The discharged smoke is taken away by an electric locomotive to be quenched under a central tower over 100 feet high, lined with acid-proof tiles and discharging water from a tank of 7,000 gallons capacity. Quenching can be closely controlled and undue moisture thus avoided. After quenching, the coke is discharged onto a wharf and left to “steam off” before it is taken to the screening plant, where it is dealt with by various belts and cutters, and sized and allotted to bins conveniently placed for automatic loading into wagons. In this plant coke will be prepared for an intended new branch of business – sized domestic fuel. The ammonia plant consists of two “Walker” stills each with a capacity of 150 tons a day, with subsidiary plant for the production of either concentrated ammonia liquor or sulphate of ammonia. There is also a tar distillation plant for reproduction of Naphtha, Naphthalene salts and various oils and tars, including road tar.

A Complete System

Powerful electrical plant is incorporated for pumping and other purposes, and there is a complete system of metering and registration. Delicate instruments measure all the gas produced and burned, and temperatures and pressures at all points of the plant can be read from a master instrument in the control room. All the steam, liquor and oil passing through the plant is metered. In the bunker “basement” housed in the control room, an electrical sub-station (containing a motor generator set of 150 kwt. and a transformer), mess room, offices, stores, and fitting and repair shops. The water for cooling the plant is stored in a tank at the top of the bunker, with a capacity of 56,000 gallons, pumped up at a thousand gallons a minute from Bolton Meadows, a quarter of a mile away.

Coke-Oven Gas

The primary product of the plant, coke-oven gas, will be produced (from 30 ovens) at the rate of three to four million cubic feet per day (according to the output) after heating the ovens and supplying other colliery requirements. From this surplus the requirements of the Wath, Bolton and Thurnscoe Gas Board, the Swinton and Mexborough Gas Board, Baker and Bessemer Steel Works, Kilnhurst and Dale Brown and Company’s Glass Bottle Works, Swinton can be met, and the plant will still have a potential capacity far exceeding present demand. It is possible, however, that new industrial outlets will be found, and the company have an eye not only to marketing gas in more distant towns, but to the possibility that the excellent factory sites in the neighbourhood may in the near future be occupied by industries requiring this form of fuel and power.

Courage And Enterprise

The new plant is a remarkable and valuable addition to the industrial resources of the district, and is also a monument to the courage and enterprise of the Manvers Main directorate, who undertook this costly scheme in the depth of unprecedented depression in the mining industry. The work of erection has been most skilfully carried out under the direction of Mr. Joseph T. E. Preston, plant superintendent for Simon-Carves Ltd. and Mr. C. P. Finn, M.Sc., engineer, and manager of the plant, for the Manvers Main Collieries Lid.